biomass pelletizing plant

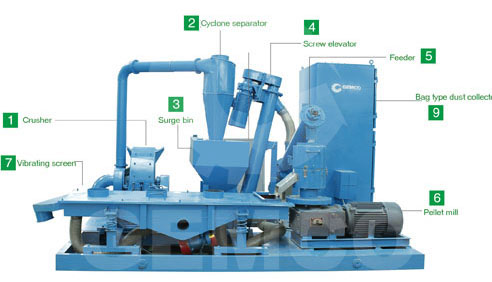

Biomass pelletizing plant is the latest new design and manufactured pellet production line for customers who want to make pellets at home for family use. The pellet plant includes pulverizer, cyclone separator, silo, feeder, pellet mill, vibrating screen, bag-type dust collector, foundation frame and electric cabinet, which are the important components. Biomass pelletizing plant can not only process bagasse, stalks and straw but also animals’ forage and fodder. The raw materials cover a wide range of sawdust, twigs, straw, peanut shells and anything you can think the biomass material our small mobile pelletizing system can make them into biomass pellets.Whole Biomass Pelletizing Plant

GPM-300R Small Mobile Pelletizing System: based on a pellet plant without a drying or packing system

The range of diameter of pellets: 6-12mm, with pellet density of 1.1-1.3t/m³ and moisture content of ≤8%

Overall size(L*W*H): 3720X2080X2080mm;

Pellet yield: 250-350kg/h

In Biomass Pelletizing Plant, there are main key parts for pelletizing.

Pulverizer

|

In pulverizer system, the pulverizer adopts crusher and hammer mill. Therefore, the output is decided by the size and moisture content of the raw materials. |

Surge bin

|

The surge bin is mainly used for storing raw materials. There are two ways to put the raw materials into the storage bin: the pretreated material will fall into the storage bin via cyclone separator; alternatively, raw material can be added in directly from the silo inlet with appropriate size. |

Feeder

|

The feeder just the shape and structure of the screw conveyor mentioned before is mainly utilized for putting the biomass materials into pellet machine continuously. |

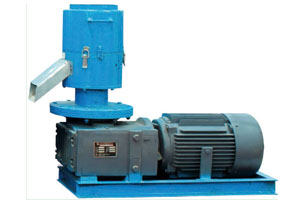

Pellet mill

|

The pellet mill is designed to process biomass raw materials with technology innovation professionally. The sphere of raw materials covers sawdust, wood shavings, straw, bamboo wastes, peanut shell, bagasse, grass and any you think the biomass materials. |

|

Salient features of pellet mill:

|

|

Bag type dust collector

|

This processing is mainly for collecting powdery material and dust. Due to the collector equipped with an induced fan, on one hand the ash content of the exhausted air will remarkably reduced; on the other hand not only can pellets be cooled, but the working environment be kept as much as clean as possible. |

Over many years' practical experience, GEMCO's products have been famous to the world especially wood pellet machine. Now the biomass pelletizing plant is our new products adopted advanced technology. We are confident that clients will be satisfied with our mobile pelletizing plant with high quality, high efficiency and competitive price. So if consumers are looking for mobile pelletizing plant, our products are your first choice. Please send e-mail us to get more information.

Why Choose Our Small Mobile Pellet Production Plant?

Our Small Mobile Pellet Production Plant

--- Produce High-Quality Pellets for You

--- Produce High-Quality Pellets for You

- Feed-in capacity of this small mobile pellet plant is consistent and stable. Under the effect of screw elevator and frequency converter, the feed-in capacity and speed can be adjusted to an adequate degree as materials and customers require, so that assures sufficient material supply to the pellet mill, and at the same time avoids surplus.

- Our small mobile pellet production plant is equipped with a startup system that you can start up and shut down the plant either manually or automatically. And if there is any accident, such a startup system will alarm the operator. This enhances the work efficiency and safety.

- Considering the requirements to workshop and the condition of shipment, our engineers have conducted a number of tests and shorten the height of our small mobile pellet production plant to facilitate the transportation and setting of it.